Advancing Towards Net Zero: Carbon Footprint Reduction and Sustainability Initiatives

January 18, 2024Background:

In West Africa, a leading telecom company finds itself grappling with several critical issues related to their diesel generators. They face spiralling operational costs due to inefficient fuel consumption and unnecessary runtime, impacting their bottom line. Frequent site outages further erode revenue by hindering customer service quality.

Additionally, delayed maintenance leads to costly repairs and disrupts vital network uptime. Moreover, inaccurate fuel data hampers supply chain management, while rising carbon emissions from inefficient operations raise environmental concerns.

This complex scenario demands a solution that tackles both the technical and financial aspects of their diesel generator management to achieve efficient operations, financial stability, and a reduced environmental footprint.

Challenges:

A leading west african telecom company was struggling with:

- Rising operational costs due to inefficient diesel generator (DG) fuel consumption and unnecessary runtime.

- Frequent site outages impacting customer service quality and causing revenue loss.

- Delayed DG maintenance leading to costly repairs and downtime.

- Difficulties in planning and supply chain management due to unreliable fuel consumption data.

- Environmental concerns arising from inefficient DG operations and rising carbon emissions.

Solution Overview:

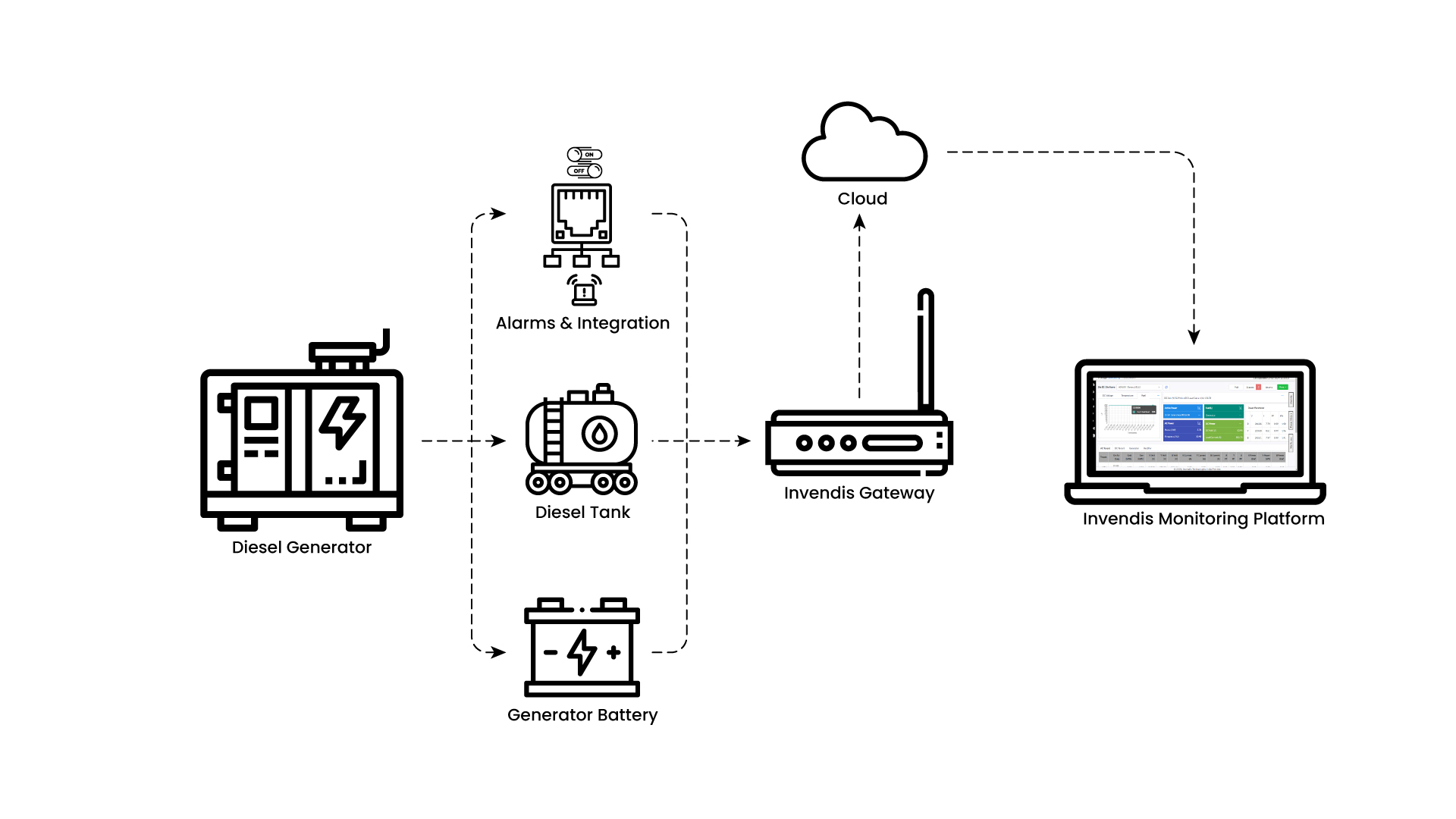

Invendis solution provided the customer real-time monitoring of the DGs while collecting real-time data on fuel consumption, runtime, and performance parameters. Cloud-based platform for centralized data visualization, analysis, and reporting. Mobile app for field technicians to receive real-time alerts and manage maintenance tasks.

Also, Helps Reducing the operational costs by optimizing fuel consumption and runtime. Improves site availability and ensure a seamless customer experience. Optimize fuel supply chain management based on accurate consumption data. Minimize environmental impact by promoting efficient DG operations and lower emissions.

Outcomes and Benefits:

Operational costs were slashed by 20% through optimized fuel use and reduced runtime. Proactive maintenance and faster outage response boosted site availability by a remarkable 95%. Additionally, maintenance costs dropped by 15% thanks to prevented unnecessary repairs and downtime.

Accurate consumption data led to improved fuel supply chain management. Furthermore, the company reduced their carbon footprint by 10% through optimized DG operations. This success story demonstrates how effective DG monitoring can deliver significant cost savings, improved service quality, and reduced environmental impact.

Conclusion:

Diesel generator operations were plagued by rising costs, outages, and environmental concerns. Yet, through strategic solutions, real-time generator monitoring & data-driven insights, they achieved remarkable results.

This case study serves as an inspiration, demonstrating how effective management and innovative solutions can transform operational challenges into resounding victories.