WFM with OSS Integration

December 20, 2021

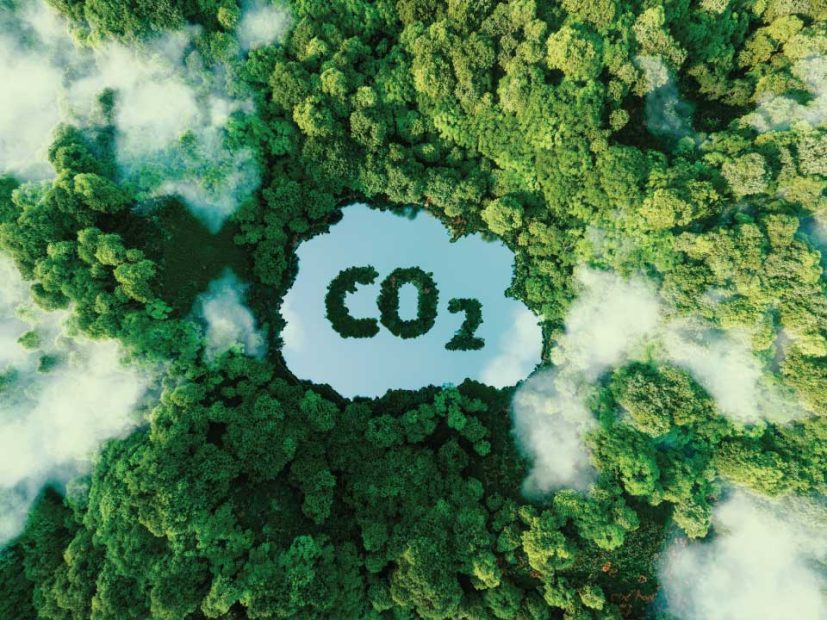

Improve Solar Plants efficiency

December 20, 2021Improve service life of generator, save fuel, reduce carbon footprint and optimize site visits

A Case Study of a customer in South East Asia

This customer is one of the largest independent owner and operator of shared wireless infrastructure. Their portfolio includes over 29,300 towers spread across several countries in the region.

Customer Implemented

- Invendis RMS IIoT System with hardware at site

- NOC application

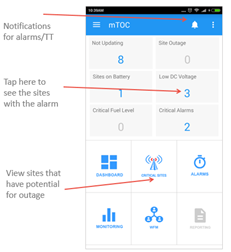

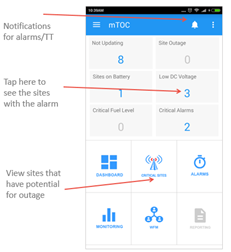

- Mobile application for field staff

- Interfaced with DG Controller

- Installed AC energy meter

- Installed DC energy meter

- Installed Battery Monitoring System

- Air-condition control module And Fuel Sensor

The Customer Gained

- Visibility of all sites

- Visibility of diesel generators, understood fuel efficiencies, CPH and overall performance

- Hybrid switched between DG & Battery and controller aircon

- Scheduled well informed roster for refuelling site visits

High Visibility, Higer Efficiency, High performance

Graphical View & Control

Invendis NOC application improves staff efficiencies with intutive user interface

- Invendis system interfaces with DG controllers to capture vital parameters that are essential for proper maintenance of the DG.

- Invendis fuel sensors measure

- Fuel level

- Fuel usage

- Fuel fill

- Sudden drop in fuel level (Fuel theft/ leak)

- The system can be configured to raise alarms as per business requirements as well as classify them into ‘Critical’, ‘Major’ and ‘Minor’ alarms

- Trouble tickets can be generated either manually or automatically.

- Fault Diagnosis which enables team to apply corrective actions about maintainance cycle

- Data Driven Prioritization of maintainance activities

Result

- Optimise maintainance cycle and reduce revenue leakage

- reveal inefficiencies in assets which can cause system unavailability, low productivity and revenue losses

- Extend asset life

Energy saving by switching ON/Off Air Conditioner

Monitor battery charge and discharge using battery monitoring systemCapitalize inbuilt algorithm within IoT hardware to switch off DG and transfer load to battery

Switch back to desired power source based on battery SOC

Site visits are optimized as follows

- Mobile application provides field staff comprehensive data on site performance/ alarms

- If the site has multiple alarms or services, all these are automatically listed for action.

- Field engineers can carry spares, indent for spares in advance

- The systems captures MTTR that helps in determining SLA , Technician competence and equipment performance which willhelp the organization for overall performance improvisations